Air Blasting Equipment

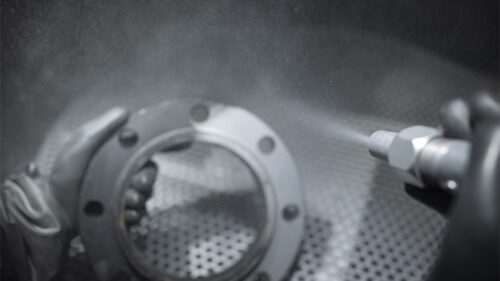

Air blasting equipment uses compressed air to propel a stream of abrasive media against a work surface for a variety of applications. Typical applications include rust and scale removal, anchor pattern creation, cosmetic finishing, coating and contaminant removal, shot peening, cleaning, stripping or cleaning composite materials, and restoration following mold or fire damage.

Selecting the right air blasting equipment depends on many variables, including size, shape, and area of the surface to be blasted. Other factors include automation needs, surface finish requirements or desired abrasive media. Air blasting requires a clean and dry compressed air supply, as oil and moisture will contaminate the work surface and blast media, impairing blasting productivity.

SurfacePrep supplies a full range of air blasting equipment, including: